Resins are among the indispensable raw materials of the adhesive industry. Obtained from natural and synthetic sources, resins enhance the mechanical and chemical properties of adhesive formulations. In this context, gum rosin and other resin types play a critical role in various applications within the sector.

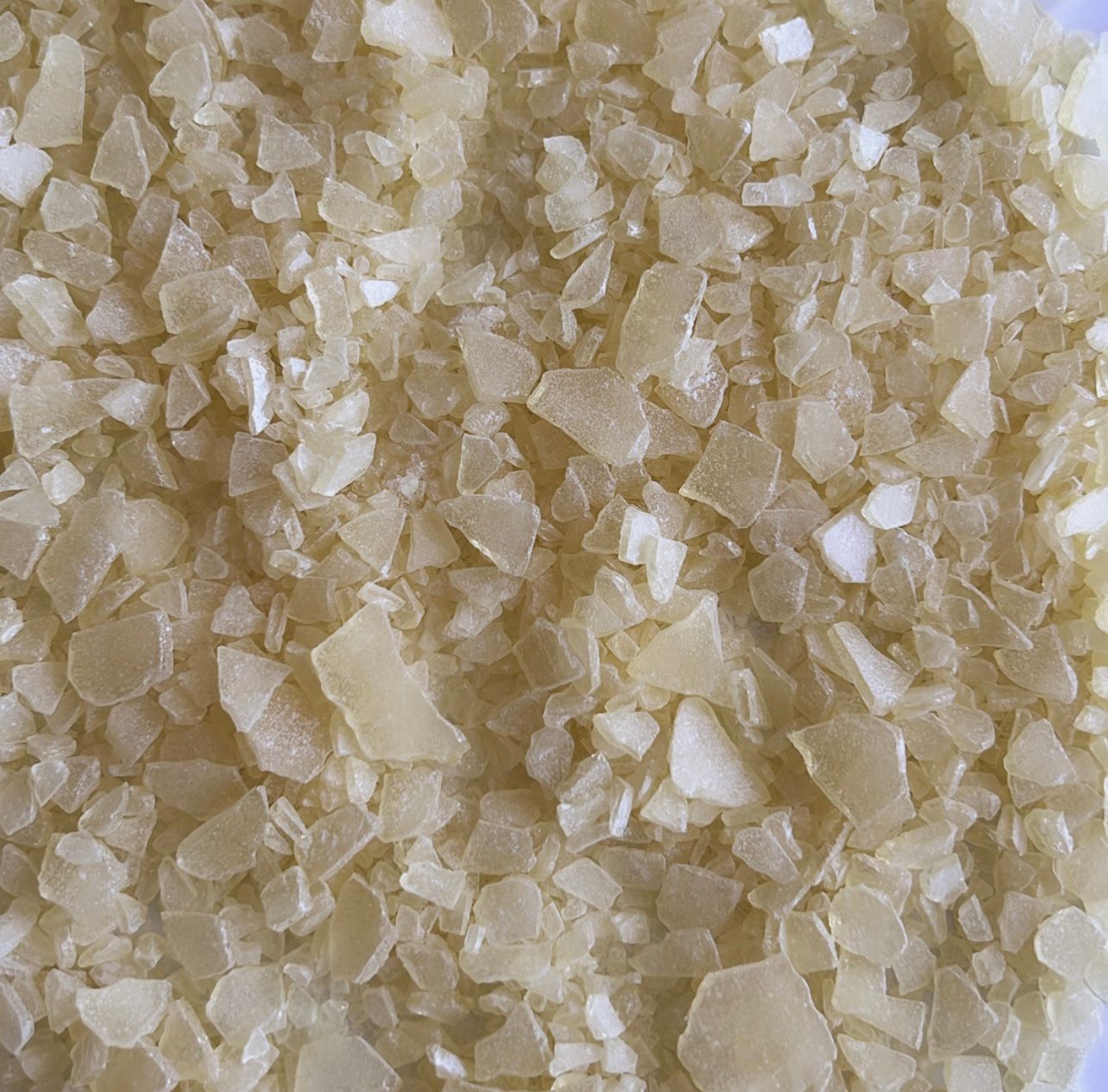

Gum Rosin: A Natural Raw Material

Gum rosin is a natural resin obtained from pine trees. It is generally used in the production of paper, paint, varnish, and adhesives. Gum rosin stands out as both an economical and environmentally friendly option. The prominent features of this resin in adhesive formulations are:

- Enhancing Adhesion Performance: Rosin improves the bonding strength of the adhesive between substrates and creates more durable bonds.

- Chemical Resistance: It provides resistance against water, alkaline, and acidic environments, which increases the longevity of the adhesive under various conditions.

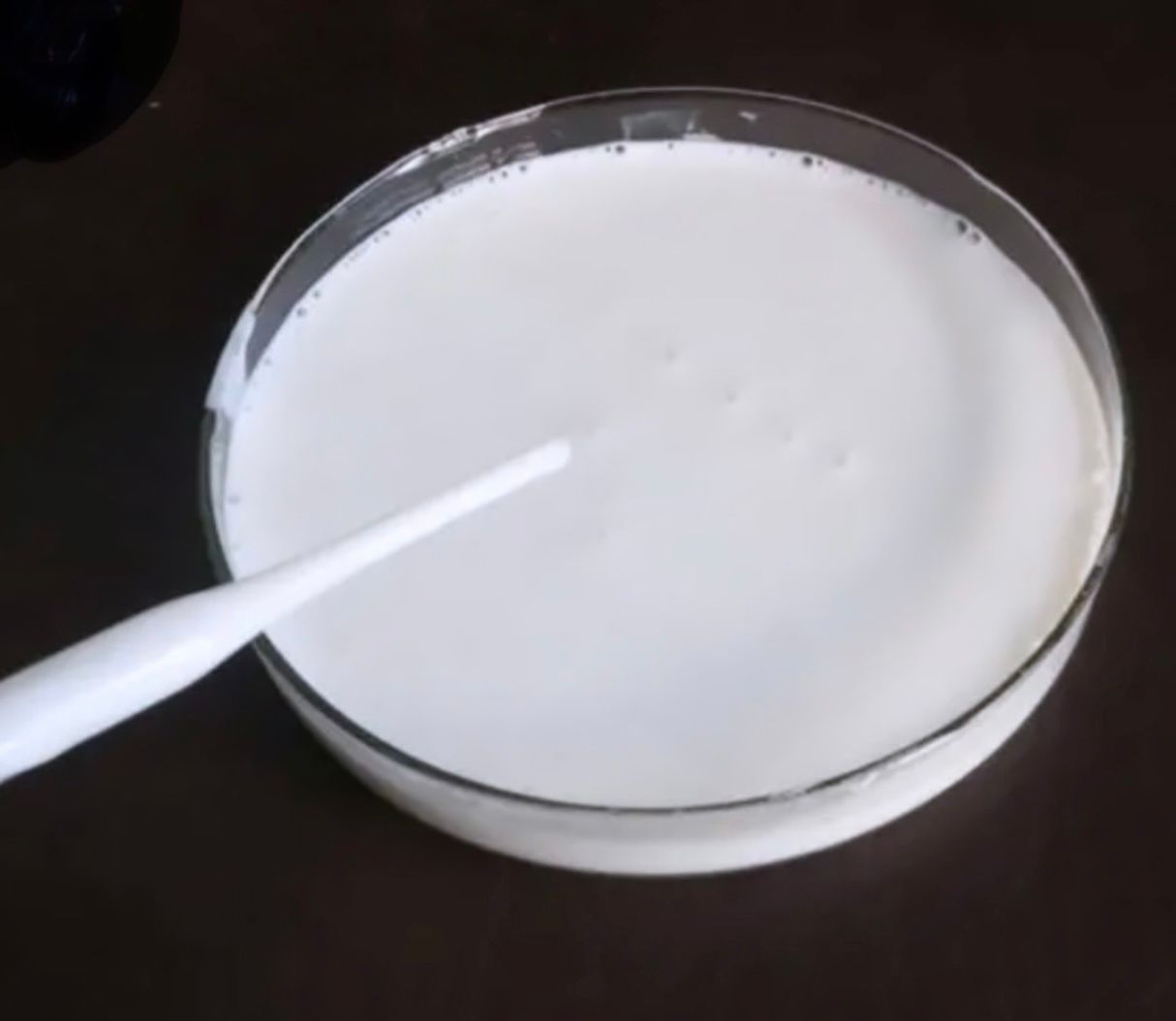

- Film Formation: Gum rosin helps in the formation of a thin and homogeneous film layer, which enhances the applicability of the adhesive.

- Versatility: Gum rosin can be easily adapted in both water-borne and solvent-borne systems.

These properties of gum rosin make it a preferred choice across a wide range, from industrial adhesives to paper glues. Particularly in paper and cardboard adhesives, rosin is widely used for providing high adhesion performance.

Other Resin Types

In addition to gum rosin, various resin types with different properties are used in the adhesive industry. These resins offer specialized solutions for diverse applications:

- Phenolic Resins Phenolic resins are known for their thermal and chemical resistance. These resins are generally used in wood adhesives and lamination applications. Especially in plywood production, phenolic resins offer durable bonding solutions.

- Epoxy Resins Epoxy resins are an ideal choice for applications requiring strength and durability. They are commonly preferred for protecting electronic components, in structural adhesives, and for bonding composite materials.

- High Heat Resistance: Epoxy resins provide mechanical stability even under high temperatures.

- Chemical Bonds: Epoxy resins form strong chemical bonds with various substrates.

- Polyurethane Resins Polyurethane resins stand out in applications requiring flexibility and water resistance. These resins are widely used in the furniture industry, textile lamination, and shoe adhesives.

- Elasticity: With their flexible structure, polyurethane resins offer resistance against impacts.

- Waterproofing: These resins do not experience performance loss in humid and water-exposed environments.

- Acrylic Resins Acrylic resins are notable for their fast-drying and transparency features. They are prominent in adhesive tapes, packaging applications, and optical adhesives.

- UV Resistance: Acrylic resins do not yellow or degrade when exposed to sunlight.

- High Adhesion: Suitable for lightweight yet durable bonding applications.

Sectoral Applications

The versatility of resins stands out in the adhesive industry in the following areas:

- Packaging: Provides strong adhesion in cardboard boxes and packaging tapes.

- Wood Industry: Enhances durability in adhesive types used in furniture, parquet, and plywood production.

- Electronics: Epoxy resins ensure the protection and fixation of electronic components.

- Automotive: Polyurethane and epoxy resins are preferred for bonding interior and exterior vehicle components.

Sustainability and Future Trends

Today, there is an increasing demand for sustainable materials in the adhesive sector. Natural resins like gum rosin play an important role in meeting this need. Furthermore, biotechnology and nanotechnology-based resin formulations have the potential to shape the future of the sector.

- Biological Sources: Resins obtained from renewable raw materials offer the potential to reduce the carbon footprint.

- Nanotechnology: Nanomaterials can be utilized for lighter, more durable, and customizable resins.

Gum rosin and other resin types are among the versatile and effective raw materials of the adhesive industry. The properties and application areas of these materials pioneer innovative solutions in the sector. With sustainability and technological advancements, the application areas of resins in the adhesive sector will expand even further.

.jpg)