Among the various materials used in industrial processes and products today, there is a group of components derived from nature and utilized in diverse applications. Rosin ester is a family of chemical compounds derived from resin extracts, a material originating from nature, and ester groups. In this blog post, we will provide a comprehensive overview of what rosin esters are, how they are obtained, and in which industrial fields they are used.

What is Rosin Ester?

Rosin ester is a chemical compound derived from naturally occurring resins and is generally synthesized through an esterification reaction. These esters are formed when resins, obtained from the secretions of various trees like pine trees, react with an alcohol. Typically, types of alcohol such as methanol or ethanol are used.

The esterification reaction is a chemical process that occurs as a result of the combination of an acid and an alcohol. In this process, resin and alcohol molecules bind together to form a compound called an ester. Rosin esters are obtained through the reaction of resins with alcohol in this esterification process.

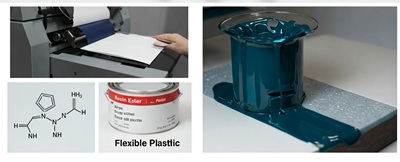

Rosin esters are generally found in a solid or semi-solid form and are used in various industrial applications. These applications include areas such as the ink and paint industry, adhesives, the plastic and polymer industry, food additives, and the paper and cellulose industry. The use of these esters offers various advantages aimed at improving product properties and enhancing performance.

Obtaining Rosin Ester

The production of rosin esters is generally carried out using a chemical process called the esterification of resins. Here are the basic steps for obtaining rosin esters:

- Resin Extraction: Resin, the basic component of rosin esters, is usually obtained from natural sources such as pine trees. These resins can be secreted from cuts in trees or collected by special methods.

- Resin Processing: The extracted resins are processed by purifying them from unwanted residues. At this stage, filtration and various other processes can be applied to increase the purity of the resins.

- Esterification Reaction: The main synthesis stage of rosin esters is the esterification reaction of resins with an alcohol. In this reaction, resin and alcohol molecules combine to form a chemical compound called an ester. The reaction usually takes place with an acid (e.g., sulfuric acid) used as a catalyst. An example of an esterification reaction can be shown as follows: RCOOH (Resin Acid) + R'OH (Alcohol) → RCOOR' (Rosin Ester) + H₂O Here, RCOOH represents the resin acid molecule, and R'OH represents the alcohol, while RCOOR' is the rosin ester.

- Product Separation and Purification: After the reaction is complete, rosin esters must be separated from the resulting mixture. This is usually achieved by distillation or various separation techniques. Various purification processes can be applied to increase the purity of the obtained rosin ester.

- Making the Product Usable: The obtained rosin ester must be brought to specific standards before being used in desired industrial applications. This stage ensures the product is suitable for specific industrial requirements.

These steps describe a general rosin ester production process; however, there may be variations in the process depending on industrial applications and the type of rosin ester to be used.

Applications of Rosin Ester

Rosin esters are a versatile group of chemical compounds with a wide range of uses in various industries. Here are some common areas where rosin esters are used:

- Ink and Paint Industry: Rosin esters are important binding agents used in the production of ink and paint. These esters help improve the surface properties of inks and paints and enhance color stability.

- Adhesives: Rosin esters are used for their binding properties in adhesives and adhesive products. They are particularly preferred in the wood and paper industries.

- Plastic and Polymer Industry: In plastic and polymer production, rosin esters are used as various additives. This helps improve the properties of plastics and enhance product performance.

- Food Additives: Some types of rosin esters are used as emulsifiers and stabilizers in the food industry. They are widely preferred for improving the texture and durability of food products.

- Paper and Cellulose Industry: Rosin esters are used in the paper and cellulose industry to strengthen the structure of paper and improve its surface properties. This is important for increasing the durability of paper and enhancing print quality.

- Surface Coating Materials: In the furniture industry and other surface coating applications, rosin esters are used in the formulation of varnishes and coating materials. This helps impart durability and aesthetic properties to surfaces.

- Cosmetic Products: Some types of rosin esters can be used as stabilizers and binders in cosmetic products, especially in skincare products.

- Rubber Industry: Rosin esters can be used in rubber production to increase adhesive properties and improve the overall performance of the rubber.

These areas demonstrate that rosin esters are used in a highly versatile manner. Each application may prefer different types of rosin esters that have specific properties and requirements.

Rosin esters are a versatile family of chemical compounds derived from nature and used in many industries. These esters are widely used in the ink, paint, adhesive, plastic, polymer, food, and paper industries. Due to being obtained from natural sources and their usability in various industrial applications, rosin esters stand out as a sustainable and environmentally friendly solution.